More than "just... an industrial accident"

Wednesday, April 19, 2023, a Stand up Forklift Operator was killed during an apparent plant forklift accident.

"We’re not sure exactly how it happened because there was no camera in the area. But it looks like he may have backed into one of the shelves and gotten pinned," Deputy Coroner Amy Sheppard. Read the fully story here.

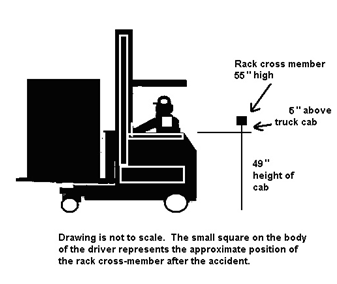

"Many stand up forklifts are built such that the operator compartment is open at the back; there is no protective structure reaching from the overhead guard to the forklift body. The operator is exposed if the forklift reverses into racking. The forklift body can ride under a horizontal rack beam, crushing the operator. See the illustration below." Read more from Forklift Action here.

Unfortunately, Stand up Forklift underride is a well-documented and widely known hazard that can easily be prevented with proper equipment, assessment and communication.

Stand up forklift underride is not “just ... an industrial accident.” It is a crushing collision that causes horrific life-altering injuries or death. Nor is it a “freak accident”

All Yale trucks come standard with features that promote enhanced operational security and safety. In their standard configuration, Yale trucks enable properly trained operators to utilize these industrial tools in a safe and productive manner.

Yale Stand-up Lift Trucks come standard with a rear post and a heightened frame in the backrest area, which are intended to provide reasonable protection to the operator in standard warehouse shelving configurations.

How to Reduce Forklift Accidents

With so many potential dangers to warehouse employees from forklifts, it makes sense that the injury level is so high. However, managers can work to create safer environments and policies when forklifts are in use.

1. Training

When you bring on new employees, you can train them how to interact with forklifts in all situations. For floor employees, you can teach them safe practices for when they are near a forklift, helping keep them safe from common incidents involving forklift operators and other employees. For example, this training might include teaching them warehouse routes that only employees or forklifts take to remain on the appropriate one.

You can help protect all employees by requiring operators to pass specialized forklift training before they can use the machinery. This training can oversee all forklift functions, from steering to securing and delivering loads, helping prevent common forklift accidents. You might require employees to retake this training periodically to remember all safety and operating procedures when using the equipment.

2. Clean, Organized Environment

Clean, organized environments are crucial for creating safe spaces where your employees can carry out daily tasks. Employees should be able to move about their work without the risk of tripping on fallen items or slipping on liquids and debris. However, these hazards can also make it more challenging and dangerous for forklift operators.

Enforce clean pathways where forklifts operate, ensuring they are clear of debris and other obstructions. When warehouses prioritize clean environments, forklift operators can safely transport and store pallets throughout the warehouse without worrying about possible risks.

3. Forklift Maintenance

While much of forklift safety is on the operators and employees, managers can help protect their employees by ensuring forklifts always function at their best. Equipment malfunctions can be dangerous to forklift operators, compromising their safety even when they have the necessary training and follow all guidelines.

Forklifts require regular servicing and maintenance. These practices can help catch malfunctions or poor performance, highlighting parts that need replacing. You can take machines that don't meet safety and performance standards off rotation, allowing employees to use only the ones that work correctly.

Establish Lockout-Tagout procedures for power equipment that needs servicing or maintenance. Lockout-Tagout mechanisms will physically prevent employees from powering on poorly functioning equipment and clearly mark them with the tags. This system can keep broken equipment off the floor and away from employees, ensuring their safety while they work and interact with machinery.

4. Safety Mechanisms

Warehouses have many procedures they can put into place to ensure increased forklift safety, including:

- Visibility: Accidents and collisions can occur when forklift operators can't see what's ahead of them. Ensure operators and other employees have the right equipment to increase visibility, from loading height specifications to proper lighting and visibility vests. Excellent visibility practices can ensure forklift operators can see threats in advance and can take the best course of action.

- Layout and signage: Your warehouse's layout can protect employees and keep forklift operations efficient. You can create various pathways throughout your warehouse, designating areas to specific procedures like forklift deliveries and on-foot processes. This system can keep employees and forklifts on separate tracks, preventing accidents. You can make these zones clear by adding signs or colors to distinguish between forklift and employee areas.

- Proper storage systems: Prevent falling items and unstable pallets by implementing smart storage systems. Store heavier items on the bottom of racks, while lighter things can go higher, ensuring increased stability when loading and unloading goods.

Introducing these habits to your warehouse can drastically increase forklift safety, covering several aspects of its hazards and protecting all employees.

5. Proper Loading Procedures

How your employees load pallets for transport can determine forklift safety. Falling items can damage client goods and potentially harm surrounding employees. Enforce proper loading procedures when using a forklift. While more items might take fewer trips throughout the warehouse, reiterate how heavier or bulkier loads can become more unstable and prone to falling objects.

Invest in Quality Equipment and Training With Medley Equipment Company

Preventing forklift accidents in warehouses starts with a comprehensive understanding of the risks but requires the right machinery and training to maintain employee safety.

Medley Equipment Company offers several forklift types, allowing you to choose the best equipment for your warehouse. Our comprehensive operator safety training program lets your forklift operators learn the essential skills they'll need before using your equipment, increasing warehouse safety.

Contact us today to discover how we can help protect your warehouse employees.